PDI Cube — US$129.00

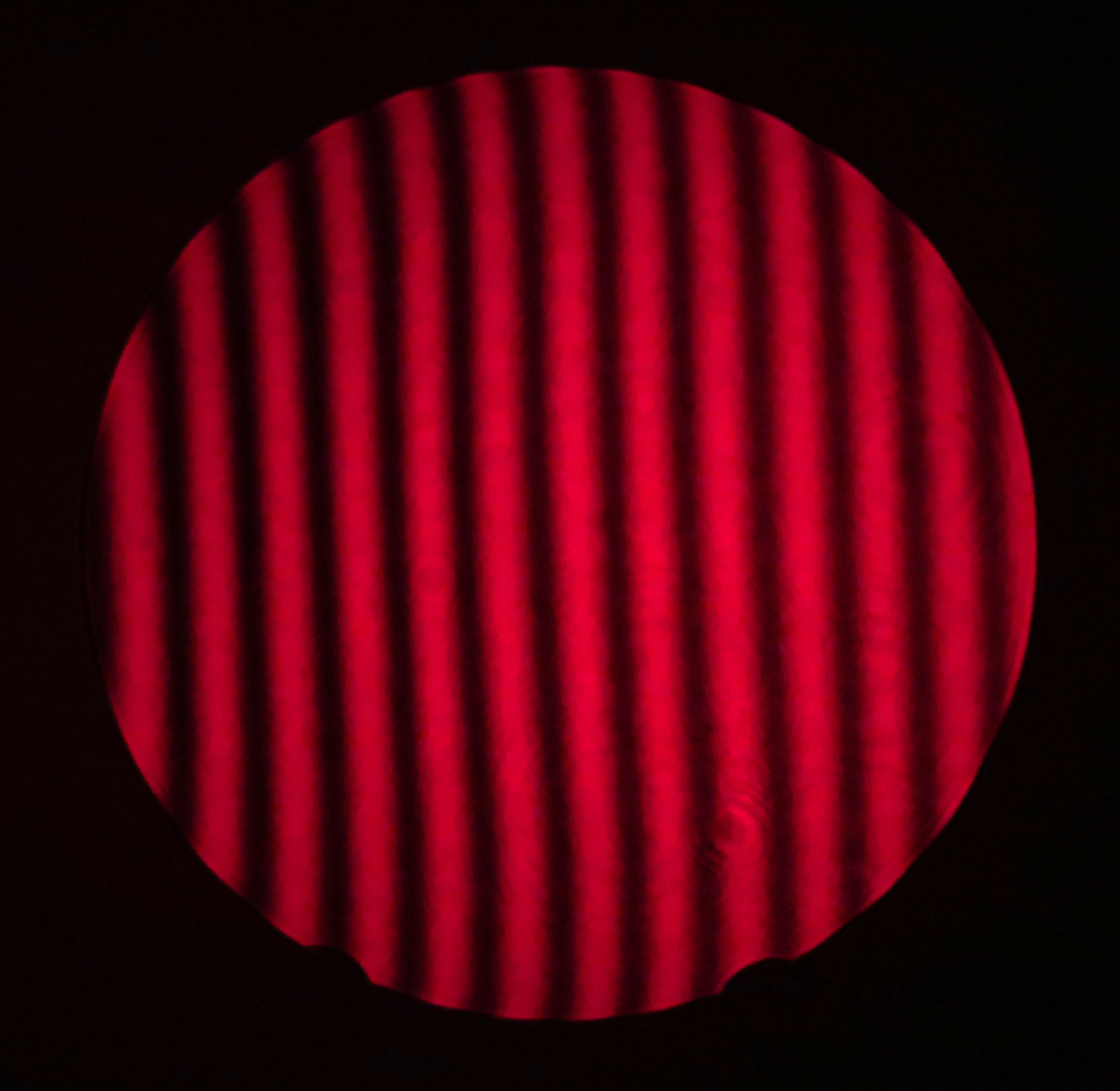

Kerry Optical Systems is pleased to offer the PDI Cube, a simple Smartt-style PDI (point-diffraction interferometer). The performance of the PDI Cube is exceptional, as shown in the interferogram of the Kerry Optical Systems concave spherical reference mirror. Interferometric results are equivalent to those obtained with the SPPDI®.

Kerry Optical Systems is pleased to offer the PDI Cube, a simple Smartt-style PDI (point-diffraction interferometer). The performance of the PDI Cube is exceptional, as shown in the interferogram of the Kerry Optical Systems concave spherical reference mirror. Interferometric results are equivalent to those obtained with the SPPDI®.

The PDI Cube is a type of common-path interferometer, which can utilize a low-coherence laser source such as those commonly found in low-cost laser pointers.

The Kerry Optical Systems PDI Cube comprises a high quality 10 mm cube beam splitter, with high efficiency antireflection coatings on two adjacent exposed faces, and two thin identical PDI plates optically bonded to the remaining faces. The PDI plates are bonded to the beam splitter cube using a proprietary method that eliminates reflections that would otherwise occur due to the refractive index mis-match between the antireflection coatings on the beam splitter cube faces and the PDI plates. This completely eliminates stray light reflections that would otherwise prevent long time-exposure photographs of low-intensity interferograms. We routinely record high contrast interferograms using 4 second, and even 8 second, exposure times.

Each of the two identical PDI plates is comprised of a 5 micron diameter pinhole aperture centered in a semi-transparent optical coating. Since the two PDI plates are identical, the PDI Cube may be used in either orientation.

The PDI Cube is designed to accept a focused input beam from a low-power laser source. The focused beam will be spatially filtered by the 5-micron pinhole aperture located on the entrance face of the PDI Cube. The diverging beam inside the cube is reflected or transmitted by the cube toward the test article. The signal beam returned by the test article re-enters the PDI Cube, and exits at the other PDI plate where a portion of the beam passes through the pinhole aperture and produces a spherical expanding reference beam. The remaining portion of the signal beam passes through the semi-transparent PDI plate and mixes with the reference beam to produce interference fringes on the camera detector. The transparency of the coating on the PDI plate is balanced so as to produce high contrast interferograms comprising a relatively high fringe count.

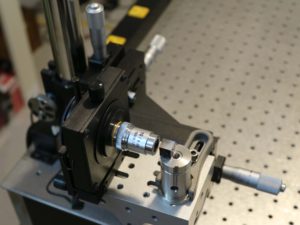

A typical setup for doing PDI Cube interferometry is shown in the photograph. As shown in the photo, the PDI Cube is affixed with double-sided tape to the top of a short mounting post. What appears to be a microscope objective is actually the shell of a microscope objective with the optics removed. This microscope objective shell has the correct inside diameter to receive a low-cost 12 mm diameter diode laser module with back-to-back collimating lenses. The microscope objective/diode laser assembly is mounted in a five-axis mount. The X-, Y-, and Z-axes of the five-axis mount are used to position the front focal point of the laser diode module on the spatial filter of the PDI Cube. (The tip/tilt feature of the five-axis mount is not used.) The five-axis mount and PDI Cube assembly are mounted together on a platform which is in turn attached to a larger three-axis linear stage system which moves the platform along three orthogonal X, Y, and Z axes. This enables fine positioning of the PDI pinhole aperture with respect to the center of curvature of the test article, which controls the curvature, spacing, and brightness of the interference fringes.

A typical setup for doing PDI Cube interferometry is shown in the photograph. As shown in the photo, the PDI Cube is affixed with double-sided tape to the top of a short mounting post. What appears to be a microscope objective is actually the shell of a microscope objective with the optics removed. This microscope objective shell has the correct inside diameter to receive a low-cost 12 mm diameter diode laser module with back-to-back collimating lenses. The microscope objective/diode laser assembly is mounted in a five-axis mount. The X-, Y-, and Z-axes of the five-axis mount are used to position the front focal point of the laser diode module on the spatial filter of the PDI Cube. (The tip/tilt feature of the five-axis mount is not used.) The five-axis mount and PDI Cube assembly are mounted together on a platform which is in turn attached to a larger three-axis linear stage system which moves the platform along three orthogonal X, Y, and Z axes. This enables fine positioning of the PDI pinhole aperture with respect to the center of curvature of the test article, which controls the curvature, spacing, and brightness of the interference fringes.

When properly adjusted so that maximum laser light passes through the spatial filter on the input face of the PDI Cube, sufficient illumination intensity is obtained to enable production of a linear set of at least 10 interference fringes at reasonable camera exposure times. Use of the PDI Cube to test uncoated optics is impractical due to excessively long exposure times.

Each PDI Cube is assembled and tested at our manufacturing facility as orders are received. We do occasionally have a small inventory of this product available for immediate shipment. Otherwise, delivery time for this product is 3 – 4 weeks after receipt of your order. If an order cancellation is received any time prior to shipment, your payment will be promptly refunded. Please see our Warranty and Returns policy here.

An order for a PDI Cube may be initiated by contacting Kerry Optical Systems, LLC by email or phone. Please visit our Contact page for our contact information. Please see our Payments page for more information.

Customers unfamiliar with products which use lasers are encouraged to read the Laser Safety section of this website.