Customer questions are posted here, along with our responses.

Q: I’ve looked at the products offered on the website and read the User Manual but there was very little information about using the SPPDI for single pass measurement besides pointing out the impediments. Assuming one has a large collimator, how can the SPPDI be configured to perform single pass measurement of a telescope or lens system?

A: The process for using the SPPDI in single-pass mode is very similar to the process for using the SPPDI in double-pass mode, except that the flat mirror used for the DPAC (double-pass under autocollimation) process is replaced by the external collimator. Also, of course, it will not be necessary to power up the internal SPPDI laser.

You will first need to insure that your external laser is polarized. The relative intensities of the test and reference beams within the SPPDI are varied by means of internal polarizer disks which are manipulated by handles which extend outside the SPPDI enclosure. Rotating the handles attached to these two polarizers varies the intensities of the test and reference beams respectively, and allow fringe contrast, spacing, and orientation to be adjusted.

Red diode lasers (650nm laser pointer type) are typically well polarized, so an external polarizer may not be necessary to achieve adequate fringe contrast. If you plan to use a HeNe laser you should check to see if it is polarized. If not, you should place a polarizer in the beam immediately in front of the laser where the beam is collimated and relatively small (in order to reduce aberrations introduced by the polarizer). If you plan to use a frequency-doubled diode laser, such as a green laser pointer, you will need to add a polarizer, since frequency-doubled diode laser beams are typically not highly polarized.

Be very careful with respect to how much laser light you are injecting into the SPPDI. The SPPDI is registered with the FDA as a Class 1 laser product only when used in double-pass mode with its internal laser source. Operation in single-pass mode with an external laser and collimator places the SPPDI outside its FDA-registered operational mode. So, be careful.

Your system under test will focus the beam from your collimator to a spot which must land on the pinhole aperture inside the SPPDI. This pinhole lies at a (virtual or apparent) distance of about 32.5 mm inside the front face of the cubical SPPDI enclosure, so your telescope focuser must accommodate that amount of standoff distance. The SPPDI is supplied with a 2″ diameter telescope adapter, so you can slide the SPPDI right into a typical 2″ diameter focuser.

Just as in double-pass mode, it will be necessary to connect up the SPPDI alignment camera to a suitable computer monitor or video monitor in order to observe the focal spot (PSF or point spread function) produced by the system under test. As you approach best focus, the PSF will become smaller and increasingly visible on the display. Note that you will also see a highly magnified image of the SPPDI pinhole aperture and surrounding fiducial cross hairs, which will assist you in aligning the PSF on the pinhole aperture. This will require the use of high precision angle adjusters located either on the system under test or on your collimator.

Another thing to keep in mind, which applies equally to both single-pass and double-pass operation, is that the SPPDI is designed to operate best with an f/10 or “slower” beam. For optical systems with focal ratios “faster” than f/10, I recommend the use of the Kerry Optical Systems Transmission Sphere and appropriate user-supplied microscope objective, along with the use of a high precision reference sphere for producing an aberration correction wavefront for removal of instrumental errors.

Q: I’d like to test mirrors and assembled telescopes. For assembled scopes I guess I’ll need an optical flat of equivalent or larger diameter to the scope- correct? I’d like to be able to get up to 12” diameter systems and a 12” flat looks prohibitively expensive.

A: Basically, there are two approaches. One approach involves the use of an optical flat (as you suggested), and the other approach relies on direct measurement of the parabolic mirror (with no optical flat) at its center of curvature, in combination with specialized interferogram analysis software.

The method which relies on the use of an optical flat can obviously be rather expensive. For best results, your flat should comprise a Schott Zerodur® substrate with a thickness of at least 1/6th of the diameter. Also, you will need to have the means to hold the flat without inducing bending stress in the flat. A mirror cell typically used to hold an astronomical mirror would work OK.

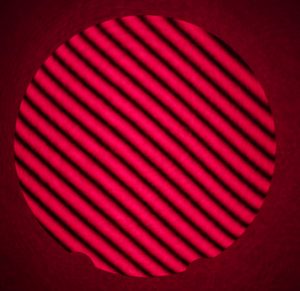

As mentioned above, it is possible to test a parabolic mirror (such as used in a Newtonian type telescope) at its center of curvature, without the need for an optical flat. This involves placing the SPPDI at the center of curvature of the vertex of the mirror. In technical terms, the SPPDI will be located at the center of curvature of the “osculating” radius of the mirror. An interferogram obtained in this way will show a high level of spherical aberration, due to the parabolic shape of the mirror. However, Dale Eason’s excellent DFTFringe software includes an “artificial null” capability, which should eliminate the spherical aberration from the computations of the surface figure. This software is available for free download from the internet.

Q: You now offer two different video camera options for aligning the SPPDI. Are there performance tradeoffs?

A: Kerry Optical Systems no longer offers a choice of video alignment cameras. We now provide a built-in video alignment camera that produces an AV2 signal, that most modern video monitors can process and display.

Q: Are there limitations when testing fast mirrors? I’m eventually hoping to make a Dall Kirkham which means fighting a pretty fast primary ellipsioid.

A: The SPPDI can successfully measure an f/2 mirror at its f/4 center of curvature (CoC). However, interferograms of faster test articles will exhibit increased aberrations due to various errors that arise within the SPPDI internal optics. These errors can be measured and removed with the aid of a Kerry Optical Systems high precision reference sphere.

Q: How do the images get from the camera into the analysis software?

A: You will need a digital camera with a large sensor and a “fast” (f/2.8 or faster) lens. You will aim the camera through the empty Instrument Port (the other Instrument Port carries the alignment camera), and focus the digital camera lens on the test article. Once you have adjusted the SPPDI polarizers and the camera polarizing filter for optimal fringe contrast, you will simply take a picture of the interference fringes (that will appear superimposed on the test article) with the digital camera.

Once you are satisfied with the interferograms that you have photographed with the digital camera, you will export the images (typically .jpg format) off of the camera memory card onto your computer where the fringe analysis software is installed. Then launch the fringe analysis software and import the interferogram images for analysis.

We have had great success using a “mirrorless” digital camera with a removable lens and APS-C size sensor, in combination with an 85mm f/1.8 mild telephoto lens.

A large camera lens aperture is required so as not to vignette the expanding beam exiting the SPPDI.

Q: What’s your reference mirror? It looks stunningly good!

A: This mirror was made by Carl Zambuto (see https://zambutomirrors.com/). We purchased this mirror from Carl and sent it to Zygo for certification. It is indeed as good as it appears on the interferogram.

Q: I have a large number of cameras and fast lenses. What will give the absolute best results?

Larger sensors = better?

Longer lenses = better?

Absolute aperture size in mm larger = better?

For example would you prefer an 85mm f1.2 on a Canon full frame, or a 42.5mm f1.2 on a Panasonic Micro4/3?

A: There are several things to consider. When you test any optical system with the SPPDI, you must position the internal pinhole of the SPPDI at the focus of the optical system you are testing. The SPPDI pinhole lies 32.5 mm deep inside the SPPDI front face (side facing the test object). The SPPDI does not modify the f/# of the system you are testing. So, the beam exiting the SPPDI will have the same f/# as the beam entering the SPPDI. So, in order to not vignette the beam exiting the SPPDI with your camera lens, you must choose a camera lens with an aperture that can accept the expanding beam without vignetting the beam, i.e., before the beam footprint grows too large for your camera lens aperture.

You can assume that the beam exiting the exit ports of the SPPDI will appear to diverge from a point that lies around 1.5″ deep inside the SPPDI body. So, by the time the beam exits the SPPDI, it is already fairly large in diameter, depending on the focal ratio of the beam entering the SPPDI. “Faster” test articles will produce beams that grow faster as they exit the SPPDI. And also, you will need to avoid bumping into the SPPDI fringe adjustment handles with your camera lens. So, altogether, you should plan to accommodate a minimum standoff distance to your camera lens of something like 3.5″.

Lenses with larger apertures will provide a larger standoff distance, before you begin to vignette the beam with your camera lens. So, choose a lens with a larger aperture so that you don’t vignette the beam. As an example, at the minimum standoff distance of 3.5″, an f/4 (“fastest” focal ratio that can be accommodated by the SPPDI) beam from a test article will have grown to a diameter of 3.5″/4 = 0.88″. An 85 mm f/1.2 lens has an aperture size of 85 mm / 1.2 = 71 mm, or about 2.8″, so you should not have any issues with vignetting the 0.88″ diameter beam.

The next thing to consider is the required size of the camera sensor. If you are going to use an 85 mm focal length camera lens, and you are going to measure an f/4 test beam, the beam footprint on the camera sensor will be 85 mm / 4 = 21.5 mm. This image size will overfill an APS-C size sensor, but will work OK with a full frame digital camera.

A Micro4/3 sensor has dimensions of 18 x 13.5mm. So, a 42.5mm f.l. lens will produce an image of an f/4 test article beam which is 42.5mm / 4 = 10.6 mm. Your image will fit well on this sensor size.

Bottom line: just use the longest focal length, largest aperture lens you can, while still getting an image that does not overfill the size of your sensor.

For a given test article, the interferogram image size on your sensor would be twice the size when shot with your 85mm lens as it would be if shot with your 42.5mm lens. Generally, you want a larger interferogram image, with more pixels covering the image.